Overview

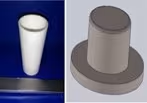

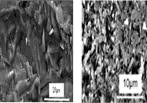

Gel casting is a near net shape colloidal processing technique for ceramics which can be adapted to develop ceramic products having various size and shapes. This technique offers advantages of machining intricate shape ceramic parts in green condition. It is possible to tailor the properties of ceramics in terms of density, mechanical properties by tailoring the composition and processing parameters. ARCI has developed SiC, Si3N4 and SiAlON products in prototype scale with the help of gel casting process and successfully sintered the products without any warpage or defect.

Key Features

- Near-net processing of complex shapes.

- Green machining

- Scalable to large size.

- Cost effective.

Major Publications

- P. Barick, D.C. Jana and B.P. Saha, Load-dependent indentation behaviour of βSiAlON and αSilicon carbide, J. Adv. Ceram. 2, (2013), 185192.

- D. C. Jana, G. Sundararajan and K. Chattopadhyay, Effect of monomers content in enhancing solid-state densification of silicon carbide ceramics by aqueous gelcasting and pressureless sintering, Ceram. Inter., 43 (2017), 4852-4857.

- K. M. Reddy and B. P. Saha, Microstructure-property correlation of porous β-SiAlON ceramics, J. Alloy. Comp., 779 (2019), 590-598.

Potential Applications

- Non-oxide based crucibles for metallurgical industry.

- Electromagnetic windows.

- Cellular SiC product for solar receiver applications.

IDPI Document

दस्तावेज़

IDPI Points

- Up-scaling is in progress for large size products.