Overview

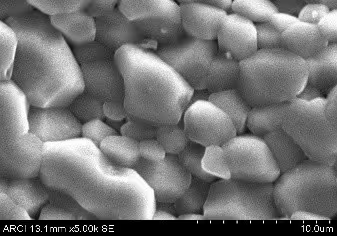

Ceramic powders encapsulated specially designed metallic can using an encapsulation welder under 10-3 Torr at elevated temperatures. The encapsulated capsule was subjected to direct consolidation by Hot Isostatic Pressing (HIP) at desired temperatures and pressures. Deformed capsule after HIP cycle was machined to release the dense compact. In a typical experiment with alumina ceramics samples was found to attain a density of 3.94 g/cc and a flexural strength of 310 MPa at a relatively low temperature of 1350oC in a single step of HIP consolidation.

Key Features

- Expertise to design cans based on the part geometry

- Engineered HIP parameters based on formulations

- Single step densification process

- Theoretical densities

- Scalable process

Major Publications

- Vacuum Encapsulation of Sub-μm Alumina Powder and Densification by Direct Consolidation through Hot Isostatic Pressing, International Conference on Advance in Materials and Manufacturing, 8-10 December-2016.

Potential Applications

- Fabrication of theoretically dense ceramic components

- Complex and simple geometries

IDPI Document

दस्तावेज़

IDPI Points

- Process established on a laboratory level

- Scale-up and prototype module fabrication is in progress