Overview

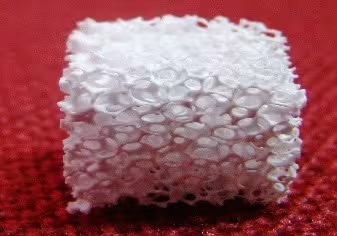

Ceramic foams are three-dimensional frame work with high porosity forming a tortuous system of interconnected cells and channels. Ceramic foams because of their inherent reticulated structure widely used as molten metal filters, catalyst supports, flame arrestors etc. Ceramic reticulated open cell foams are commonly processed by a polymer sponge processing.

Key Features

- Engineered pore densities, formulations, dimensions and shapes

- Flexibility in process to achieve desired thermo- mechanical properties

- Low pressure drop in combination with tortuous path

- Light weight ceramics

Major Publications

- Quasi-static compression behavior of nickel oxide, nickel oxide: zirconia, nickel:zirconia and nickel foams, Ceramics International, 42 (2016) 10572–10578

- Development of Cordierite based Reticulated Foams with Improved Mechanical Properties for Porous Burner Applications, Transactions of Indian Ceramic Society (In press)

Potential Applications

- Substrates for solar thermal applications

- Bio-medical scaffolds

- Catalyst substrates for pollution control

- Hot gas and molten metal filters

IDPI Document

दस्तावेज़

IDPI Points

- Polymeric sponge processing is established for various ceramic formulations

- Capability to develop the process based on the application